Grinding - NO.4 / NO.6 / HL / SB

A grinding finish on stainless steel, also called

The process uses

-

![]()

INSIDE DIA

500mm Φ - 610mm Φ

-

![]()

COIL WEIGHT

Max 20mt

-

![]()

WIDTH

1600mm

-

![]()

THICKNESS

0.28mm - 3.5mm

-

![]()

STEEL GRADE

301 / 304 / 304L / 316 / 316L / 410 / 420 / 430 / 439 / 443 AND OTHERS

Get a quote for the processing within 48 hours

-

![]()

Range Hood

-

![]()

Microwave Oven

-

![]()

Coffee Maker

-

![]()

Ovens

-

![]()

Sterilizer, Dishwasher

1. Only use good steel from big factories, with MTC Report for each roll.

2. Use the best machines to make the steel finish super shiny and nice.

3. It's acceptable to change the grinding pattern to match what you want.

4. Customized special strips are acceptable.

5. Customized special cut-to-length are acceptable.

6. PI / PE / Laser PE are available on request.

-

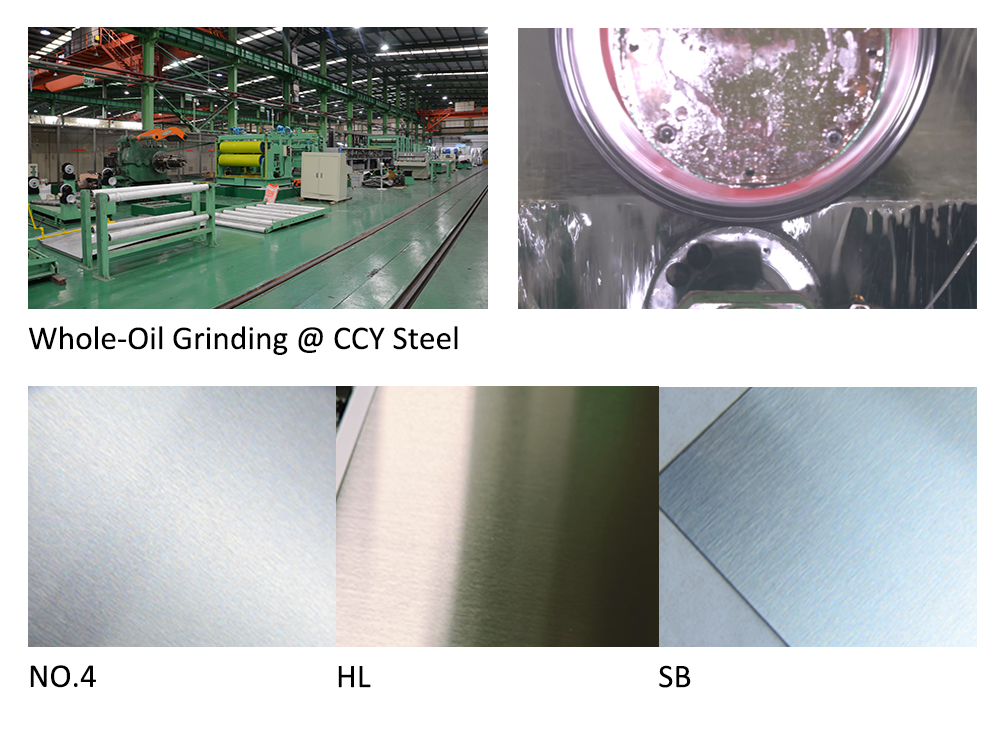

Whole-Oil Grinding Technology - For a Great Look

Different ways of grinding can make a big difference in how the stainless steel looks, even if everyone uses the same amount of time and money on good steel. CCY use Whole-Oil Grinding machine with sand belts to grind the finish. This is an unique technique that uses only oil to polish the steel. It has two big benefits compared to dry and wet grinding:

1. The oil helps tosweep away most of the tiny metal shavings that come off during the grinding, which helps the steel maintainhigh corrosion resistance on the grinding surface.

2. The oil-based process helps keep the steelflat and straight , even when it gets hot from grinding.

The cost of the grinding process might seem small compared to the whole purchase, but it can make a big difference in which company people choose to work with. In this case, CCY can help you win in the competition.![]()

-

Those competitive mill factories we are working with

We source our stainless steel from top-tier factories to ensure the highest quality. Some of the major mills we partner with include

Jisco, Baoxin, Posco, Tisco, Lisco, Outokumpu, Yuanlong, JFE, NSSC, YJGF, Delong, HWHG etc.

We often purchase large coils weighing between11~12 tons from these factories driectly. In this way, we receive the highest quality stainless steel. These mills have stringent quality control processes and provideMTC for every batch, confirming that the material meets international standards likeEN, JIS, AISI, ASTM, GB, DIN . This consistency is crucial for our products. -

What's the Difference Between HL and SB Finish?

HL and SB finishes give different looks because they use

different belts and grit sizes .

HL Finish : Also known as hairline finish, HL islike the fine lines as thin as hair . It's straight andgoes on without any breaks . It's not as shiny as other finishes like NO.3, NO.4, and NO.6. Imagine it like the smooth, straight hair on someone's head. The most common HL finish you'll see is between #180 to #240. It's a simple look, but it's been a favorite for a long time.

SB Finish : This is theScotch Brite finish. It's a semi-dull brushed finish with even grains, made withfiner stuff than NO.4, NO.5, and NO.6 . The Scotch Brite finish has asmooth, soft, and delicate look with a low shine and a one-way pattern . It's great for inside buildings, elevator panels, and kitchens.![]()

-

Benefits of Stainless Steel Brushing

CNC full oil grinding unit is the most cutting-edge grinding equipment in the current stainless steel surface grinding process, which can increase the gloss by % and corrosion resistance by % compared with the ordinary water-oil roll grinding, with uniform and stable sand samples, and the waste produced in the production process will not pollute the environment. Jianchunyou's CNC oil grinding line has extremely high production efficiency and stable equipment, which can handle xx tons of xxmm sanding orders per day.

![]()

Frequently Asked Questions

Stainless steel grinding FAQ

-

1. What standards do you follow?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.

-

2. How long is the delivery time?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.

-

3. What are your payment terms?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.

-

4. Can you provide quality documents?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.

-

5. Do you provide samples and manufacturing consultation?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.

-

6. Besides stainless steel grinding, what other surface process services do you offer?

We manufacture a large number of different sanded finish stainless steels for a variety of projects. All of these materials have excellent corrosion resistance and a fine sanded surface that helps them increase the competitiveness of their products.